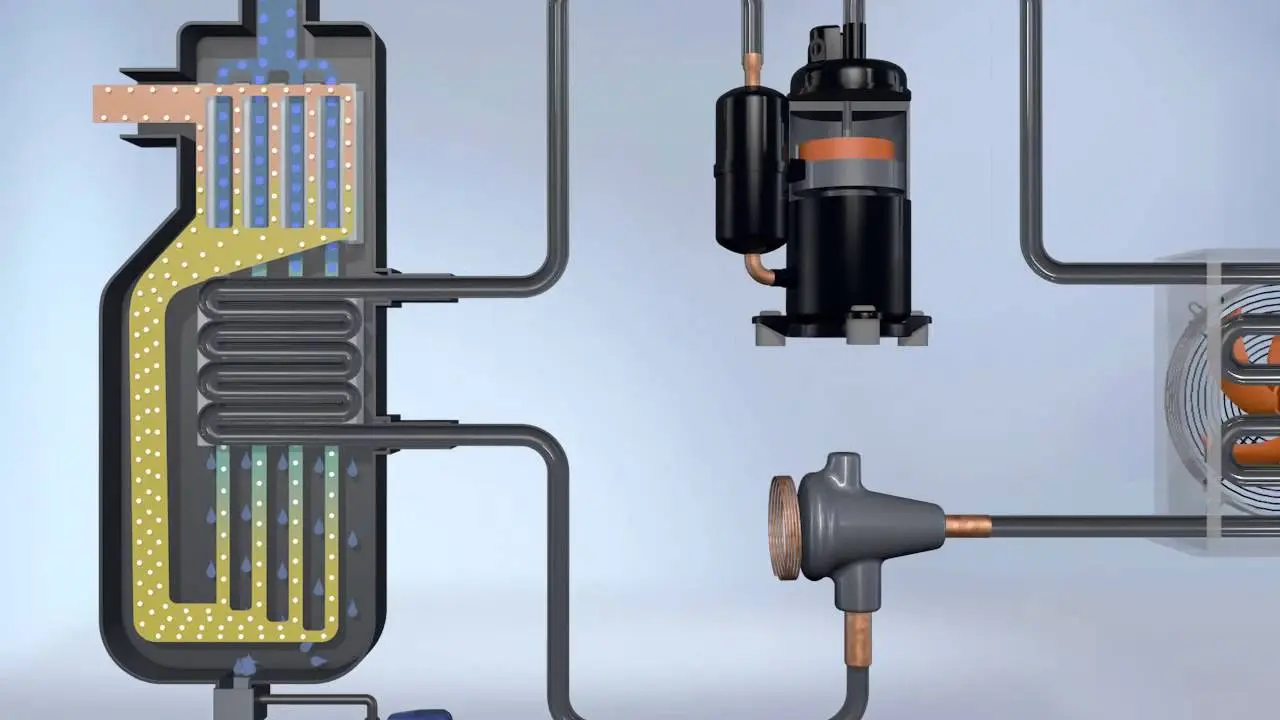

An air compressor dryer is a device used to remove moisture and contaminants from compressed air. It is typically installed in the compressed air system after the air compressor and before the point of use. The primary purpose of an air compressor dryer is to ensure that the compressed air is clean, dry, and free from impurities, making it suitable for various applications.

Desiccant Dryers: Desiccant dryers use a material, such as silica gel or activated alumina, to adsorb moisture from the compressed air. They typically consist of two chambers filled with desiccant material. While one chamber is actively drying the air, the other is being regenerated by purging it with dry air or using heat. Desiccant dryers can achieve extremely low dew points, making them suitable for applications requiring very dry air, such as in electronics or pharmaceutical industries.